Stress-free cattle weighing systems

Automatic check weight scale, also known as the weight selection machine. Is a widely used in pharmaceutical, food, chemical and other industries of automatic weight inspection equipment production line. It can detect the overweight and underweight unqualified products in the production line in real time.

What is a check scale? Why use it?

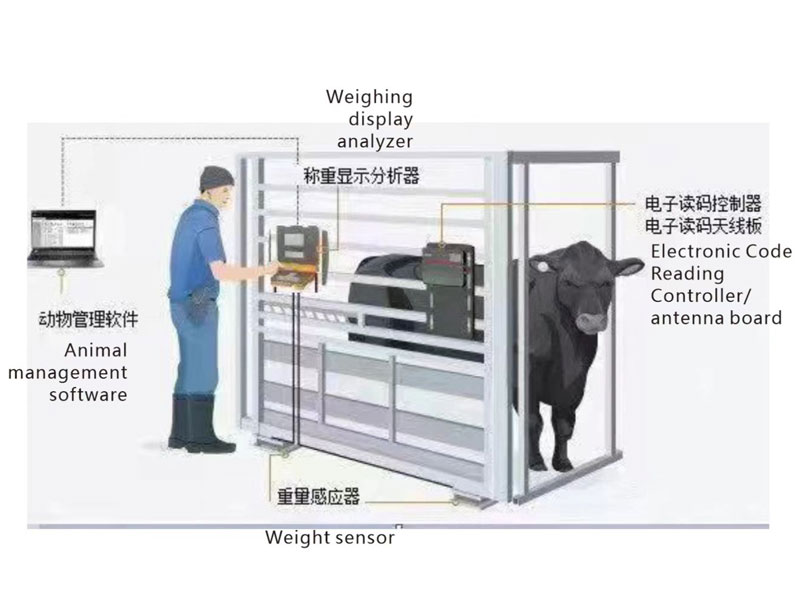

Stress-free cattle weighing systems

Current beef weighing systems require a periodic workload .These are usually labour-intensive solutions. The need to drive animals away from their place of residence causes additional stress, which can have a negative impact on both production and welfare. In addition, while moving, the animals and the people who handle them can be injured, and therefore it creates additional risks by creating dangerous situations. The disadvantage of the existing systems is that weighing animals e.g. once per month, which is most common in the case of cattle, causes the loss of a significant amount of valuable data in comparison to a system that allows weighing animals several times a day. As a result, additional information for herd management is generated, which is simply not available using current systems.

The proposed solution is a response to the disadvantages of the most commonly existing solutions. The scale records data automatically, so when installed in the watering area of the animals, it does not require any additional workload for weighing the animals. It is stress-free for animals, because the weights are recorded in the place where the animals are located anyway without the stress by moving them. Without the need of moving animals by staff makes the handling of animals much safer compared to the currently used solutions. Furthermore, multiple body weight recordings per day generate additional data that can be analysed and are useful for herd management.

With common animal weighing systems this cannot be done due to the lower frequency of weighing animals . An additional advantage of the proposed solution is also the possibility of obtaining data on water consumption by individual animals along with data on drinking behaviour (frequency of using the drinker, time spent in the drinking zone, the amount of water drunk during a single visit or the schedule of a visit to the drinking zone during the day).The main advantage of automatic weighing systems is the fact that it is labour free. In a herd of 100 head, it usually takes at 3 hours to move them through the scale, with a cost of 30 euro.

Moreover, it is stress free which increases production efficiency of growing cattle. But most importantly it is safe for staff and animals,I would have never expected that gathering data on body weight of my beef cattle would be that easy, said Lukasz the beef farmer. Moreover, now I’m getting much more information on the single individual compared to only once a month using the previous system.